+86 18968869621

+86 18968869621

In hazardous environments, safety is always a priority. Proper illumination is crucial for worker safety and operational efficiency. This is where Explosion Proof Lights come into play. These specialized lights are designed to withstand extreme conditions. They are essential for areas with flammable gases or dust.

Explosion Proof Lights are built to prevent ignition. They feature rugged, durable constructions to endure harsh impacts. The right lighting can reduce accidents and improve visibility. In many cases, choosing the right light is not straightforward. Many options exist, but not all are suitable for every environment.

Some potential buyers may overlook important features. For instance, brightness levels, energy efficiency, and lifespan should be considered. It's easy to make mistakes when selecting these lights. However, ensuring safety should always come first. The right lighting can make a significant difference in preventing accidents and ensuring the safety of personnel. Therefore, understanding the various types of Explosion Proof Lights is essential for any business operating in risky environments.

In hazardous environments, safety is paramount. Explosion proof lights play a crucial role in ensuring that spaces are well-illuminated without the risk of ignition. These specialized lights are designed with durable materials, capable of withstanding extreme conditions. They provide visibility even in the most challenging settings, such as oil rigs or chemical plants, where flammable gases may be present.

Understanding the importance of these lights goes beyond mere compliance. They can prevent accidents. Without proper lighting, workers may face increased risks. The consequences of inadequate visibility can be devastating. However, not all explosion proof lights are the same. Quality control is essential. Some products might not meet safety standards. This emphasizes the need for thorough evaluations before selection.

Moreover, installation and maintenance matter greatly. Even the best light source can fail if not correctly installed. Regular checks ensure reliability. Safety protocols should include routine inspections. It’s vital to remember that even small neglect can lead to significant dangers. These lights not only illuminate but also safeguard lives, driving home the importance of their correct usage and upkeep.

In hazardous environments, effective explosion proof lighting is crucial. These lights can withstand extreme conditions. Look for rugged materials that resist impact and corrosion. Such durability ensures long-term performance in tough settings.

Another key feature is high luminosity. Bright lights enhance visibility, reducing risks during operations. Adjustable brightness levels are beneficial for different tasks. This flexibility helps in various lighting scenarios. Moreover, energy efficiency is essential. Long-lasting bulbs minimize maintenance costs.

Finally, consider certification from relevant safety standards. It's vital to verify that lights meet industry requirements. This offers assurance of safety and reliability. However, not all products live up to expectations. Regular checks and evaluations are necessary to ensure optimal performance. Striving for improvement is always important.

Hazardous environments present unique challenges. Spaces such as oil refineries, chemical plants, and mining operations often contain flammable substances. In these situations, standard lighting can pose serious risks. Explosion-proof lights are essential to ensure safety and proper visibility.

When working in confined spaces, like storage tanks or silos, specialized lighting is crucial. These areas often have limited ventilation, increasing the risk of gas accumulation. Choosing the right light, therefore, is vital. Make sure the lights are rated for those high-risk zones.

Tips: Always check for compliance with local safety regulations. Assess the lighting needs based on the specific tasks performed in the area. Choose lights that are durable and easy to install.

Electrical rooms also require special consideration. They often house sensitive equipment. Proper lighting reduces the chance of accidents. The brightness and position of lights should minimize shadows while maximizing visibility.

Tips: Regularly inspect lights for damage. Replace any faulty units immediately. Additionally, consider the use of emergency lighting in case of a power failure. Keeping these areas illuminated can be life-saving.

In hazardous environments, selecting the right explosion-proof lights is crucial. Various brands and models offer different features. Look for lights with sturdy housing. Materials like aluminum or polycarbonate resist impact and corrosion. These lights must also meet safety standards.

When considering explosion-proof lights, balance quality with cost. Some models may offer advanced technology but at a premium price. Ensure your choice fits the specific conditions. For example, wet areas need more robust waterproof ratings. Reviewing specifications can be time-consuming. Consider asking colleagues for recommendations.

Tips for choosing lights include checking the lumen output. Higher lumens mean brighter lights. Don't overlook the beam angle; wider angles illuminate more space. Also, verify the light's energy efficiency to save on costs. Regular maintenance of your lighting system is vital. Dust and grime can reduce effectiveness over time. Review your choice regularly to ensure optimal performance.

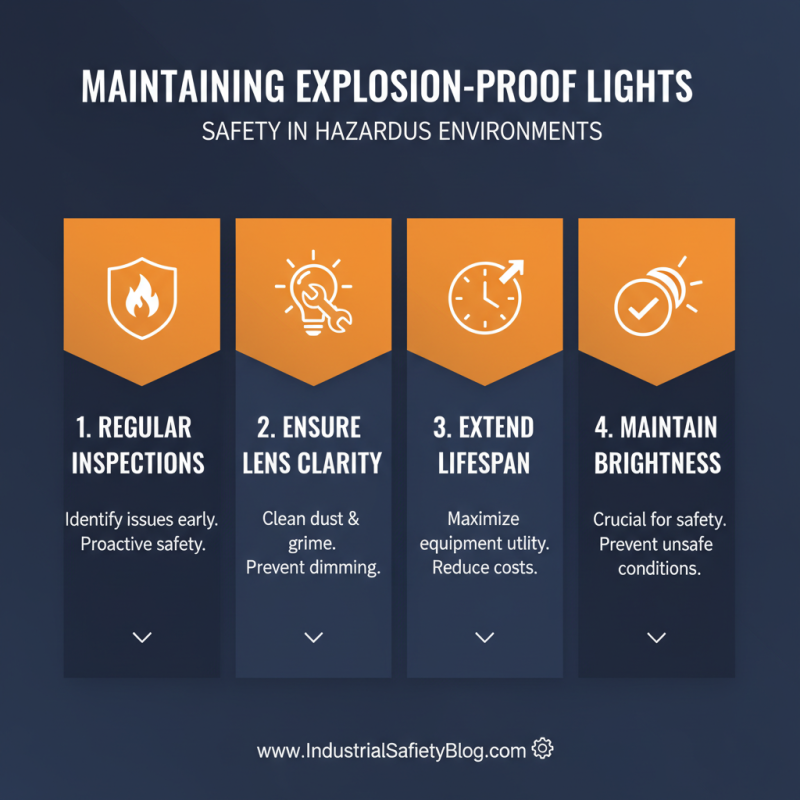

When working in hazardous environments, maintaining explosion-proof lights becomes crucial for safety. Regular inspections can identify potential issues early. This proactive approach extends the lifespan of the lights. Ensure the lenses are clean and free from debris. If they are coated with dust or grime, illumination suffers. This may lead to unsafe conditions.

While it is easy to overlook routine maintenance, problems can arise quickly. Corrosion is a common issue. It can damage the structural integrity of the lights. Regular checks can help catch these signs. Replace worn parts immediately. This might seem tedious, but it’s essential for safety compliance.

Training staff on proper care is another key factor. Not everyone understands the importance of these lights. Providing training can elevate awareness. Encourage a culture of vigilance regarding equipment safety. Always document any inspections or repairs made. This helps maintain compliance with safety regulations. These steps ensure reliable illumination in high-risk areas.